Folding boxes are among the most adaptable and eco-friendly packaging formats used today. Combining aesthetic appeal, structural reliability, and cost efficiency, they have become the preferred solution for industries like cosmetics, electronics, food, and pharmaceuticals. As brands demand smarter and greener packaging, Kardboards leads the innovation curve with folding box designs that deliver both elegance and practicality.

What Are Folding Boxes?

Folding boxes, also known as folding cartons, are made from paperboard or kraft materials that are die-cut, creased, and pre-glued to allow flat shipping and easy assembly. These boxes are ideal for high-volume production and customizable branding.

Folding boxes save up to 80% of storage and transportation space, making them one of the most efficient packaging solutions available for manufacturers and exporters.

Types of Folding Boxes

- Straight Tuck End (STE): Common for lightweight retail items; offers clean presentation with top and bottom tuck flaps on the same side.

- Reverse Tuck End (RTE): Provides quick assembly and compact design with opposite tuck flaps.

- Crash Bottom (Auto-Lock): Designed for heavier items; bottom locks automatically when erected for extra stability.

- Seal End Boxes: Common in food packaging, sealed with adhesive for tamper-proof protection.

- Window Boxes: Feature transparent PVC or PET windows for product visibility and consumer engagement.

Materials Used in Folding Box Production

Kardboards offers a diverse range of materials to suit both aesthetic and functional needs:

- White SBS (Solid Bleached Sulfate): Premium smooth surface for luxury printing and high-end cosmetics.

- Kraft Board: 100% recycled, eco-friendly material ideal for natural or organic brands.

- CCNB (Clay Coated News Back): Economical yet durable for mass-market packaging.

- Metallic or Foil Laminated Boards: Used for luxury packaging requiring visual brilliance.

- Recycled & FSC-Certified Boards: Sustainable choices aligned with green brand values.

Smart Design Meets Functionality

Modern folding boxes are engineered for more than just containment. They incorporate intelligent features such as QR codes, NFC chips, and AR visuals to engage customers digitally. Brands can embed smart labeling or authentication systems to verify product genuineness and enhance traceability.

At Kardboards, structural engineers and designers collaborate to ensure every fold, crease, and flap enhances both usability and brand experience.

Sustainability and Environmental Impact

The folding box format inherently supports sustainability. It reduces material usage, supports recyclability, and minimizes transportation emissions due to its flat shipping design. Kardboards further enhances this eco-benefit by using:

- Water-based inks and solvent-free coatings

- Fully biodegradable adhesives

- FSC-certified paper sources

- Optimized layouts to reduce paper waste during die-cutting

Folding Box Applications Across Industries

- Cosmetics & Beauty: Premium printed cartons with matte, gloss, or foil finishes.

- Electronics: Sturdy boxes with inserts for protection and presentation.

- Food & Beverage: Recyclable cartons for chocolates, cereals, and snacks.

- Healthcare & Pharma: Tamper-proof, barcode-enabled folding boxes.

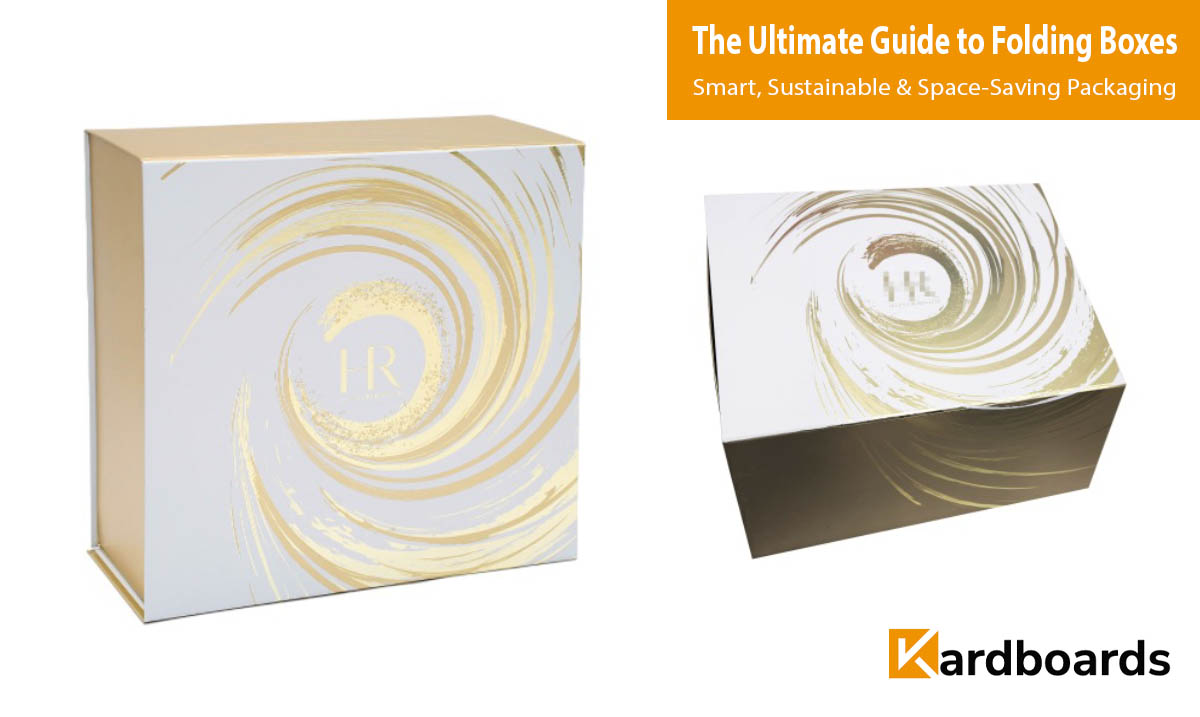

- Luxury Goods: Specialty folds, magnetic closures, and embossing for elegance.

Why Kardboards is a Trusted Folding Box Manufacturer

As a leader in China’s packaging industry, Kardboards combines global standards with efficient local production. Every folding box goes through strict quality checks — from board calibration and color matching to die precision and structural integrity testing. The company’s state-of-the-art facility integrates printing, lamination, foil stamping, and gluing, ensuring consistent quality at scale.

Kardboards serves top brands in Europe, the USA, and Asia, providing custom-engineered solutions for retail, e-commerce, and luxury packaging segments.

Frequently Asked Questions

What makes folding boxes eco-friendly?

They’re made from recyclable paperboard and shipped flat to save transport energy, reducing carbon footprint significantly compared to rigid boxes.

Can folding boxes be used for luxury products?

Yes. With premium finishes like soft-touch lamination, gold foil, and embossing, folding boxes can achieve a luxurious appearance while staying lightweight.

Are folding boxes strong enough for heavy products?

Crash-bottom and reinforced designs can safely support heavier items, making them ideal for electronics or glassware packaging.

Does Kardboards offer custom designs and printing?

Absolutely. Kardboards provides complete design-to-delivery solutions including 3D mockups, structural testing, and multi-finish printing options.