A blister container is a type of pre-formed, plastic-based packaging that securely seals a product within a molded cavity, usually backed by paperboard, aluminum foil, or plastic film. It’s widely used for pharmaceutical tablets, consumer electronics, toys, tools, and cosmetics due to its transparency, durability, and tamper-resistance.

At Kardboards, we manufacture custom blister containers using advanced thermoforming and vacuum forming technologies — ensuring precise fit, clarity, and protective sealing for every product type.

Structure of a Blister Container

Blister containers consist of two main components:

- Formed Cavity: Made from plastic sheets such as PVC, PET, PETG, or PS, heated and shaped into pockets or cavities that hold individual products.

- Lidding Material: Usually aluminum foil, coated paperboard, or plastic film that seals the cavity through heat or adhesive bonding.

This combination ensures visibility, protection, and tamper evidence while maintaining low production costs and lightweight construction.

Common Materials Used

- PVC (Polyvinyl Chloride): Cost-effective and easy to thermoform, ideal for general retail packaging.

- PET/PETG (Polyethylene Terephthalate): Highly transparent, recyclable, and durable — used in eco-friendly applications.

- PS (Polystyrene): Offers rigidity and form stability for shaped containers.

- Aluminum Foil: Used in pharmaceutical blister packs for moisture and light resistance.

Kardboards offers sustainable alternatives like RPET and bio-based plastic films to reduce environmental impact.

Types of Blister Containers

- Face Seal Blister: Plastic blister sealed directly to a paperboard backing card.

- Full Face Blister: Covers the entire front of the card, offering added protection.

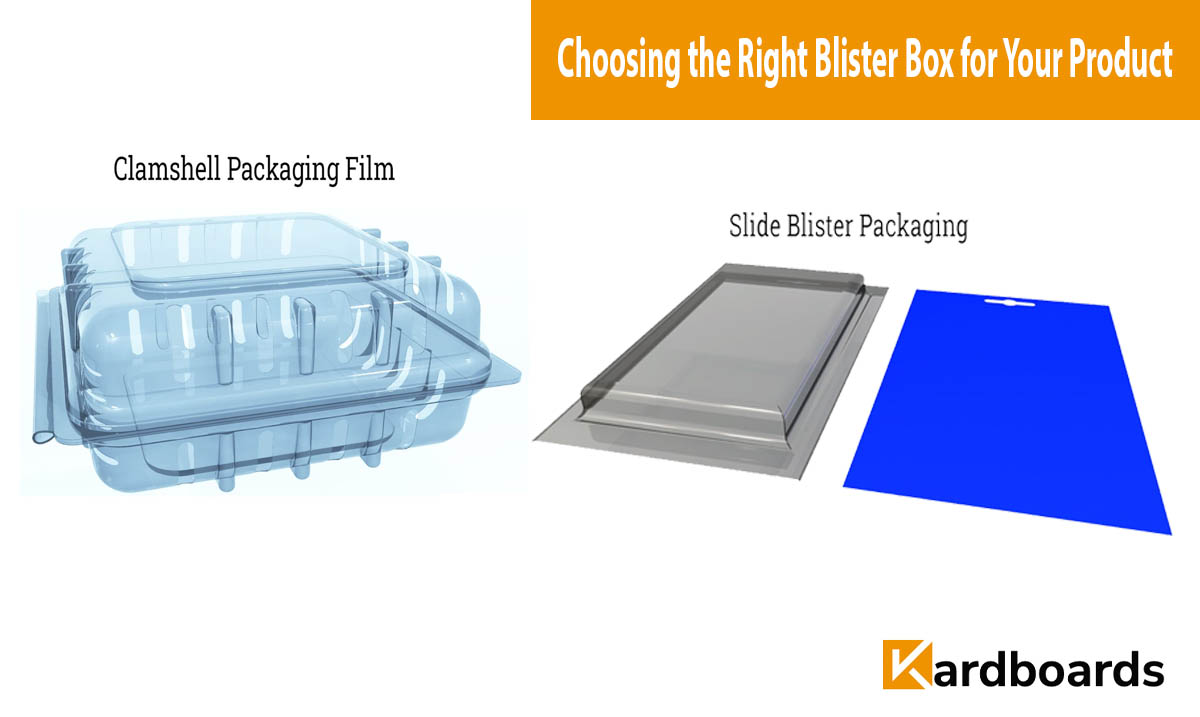

- Clamshell Blister: Two halves joined by a hinge, forming a reusable container.

- Slide Blister: The blister slides into a folded paperboard card without sealing.

- Pharmaceutical Blister Pack: Cavity sealed with aluminum foil for individual tablets or capsules.

Applications of Blister Containers

- Pharmaceuticals: Tablet and capsule packaging with tamper-proof, moisture-resistant protection.

- Consumer Goods: Packaging for batteries, toothbrushes, tools, and electronics.

- Cosmetics: Display packaging for products like razors, lip balms, and skincare kits.

- Food Items: Blister trays for confectionery and ready-to-eat meals.

Blister containers allow consumers to view the product clearly while ensuring hygiene, authenticity, and brand appeal.

Advantages of Blister Containers

- Product Visibility: Transparent cavity enhances product display and consumer trust.

- Tamper Evidence: Prevents unauthorized access and maintains product integrity.

- Durability: Offers excellent resistance to impact, dust, and moisture.

- Cost Efficiency: Lightweight and suitable for high-volume manufacturing.

- Customizability: Easily shaped, printed, and branded for visual impact.

Why Choose Kardboards for Blister Containers?

- Precision thermoforming with high-clarity plastic films.

- Eco-friendly materials — PET, RPET, and biodegradable options available.

- Advanced sealing technology ensuring strong and clean finishes.

- Full design-to-production service for retail and industrial sectors.

Frequently Asked Questions

What is a blister container made of?

Blister containers are made from thermoformed plastic such as PVC, PET, or PS, sealed with a paperboard or aluminum backing.

What are blister containers used for?

They are used to package tablets, tools, electronics, toys, and other consumer products securely while maintaining product visibility.

Are blister containers recyclable?

Yes, most blister containers made from PET or RPET are recyclable. Kardboards offers sustainable blister options compliant with global eco standards.

How are blister containers sealed?

They are sealed using heat, pressure, or adhesive bonding between the plastic cavity and backing material.

Can blister containers be customized?

Absolutely. Kardboards provides full customization — size, shape, cavity depth, and printed inserts tailored for brand presentation.