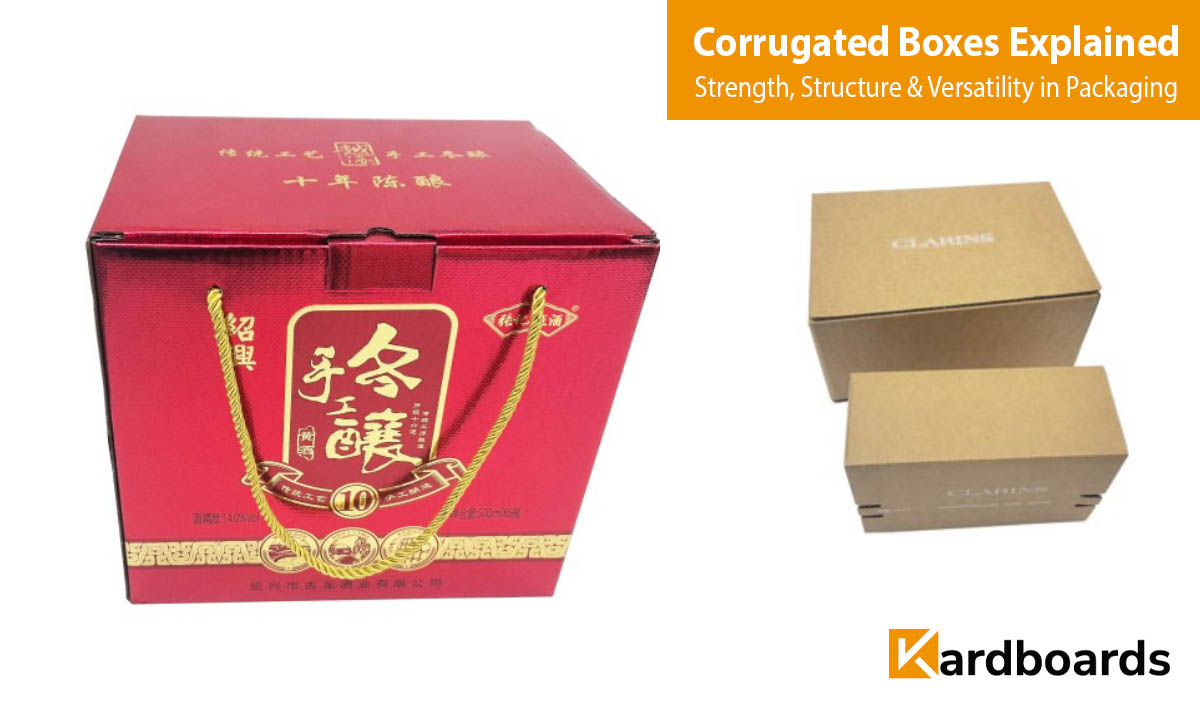

Corrugated boxes are among the most reliable and widely used packaging solutions in the world. Combining lightweight strength, design flexibility, and eco-friendliness, they have become the go-to choice for industries ranging from e-commerce and retail to heavy-duty industrial shipping.

At Kardboards, we specialise in creating high-performance corrugated packaging tailored to the specific requirements of your brand and product.

What Makes Corrugated Boxes Unique?

Corrugated boxes are made from multiple layers of paperboard — typically one or more fluted (wavy) sheets sandwiched between flat linerboards. The fluted layer acts like a cushion, protecting contents from shocks, pressure, and impact. This engineering gives corrugated packaging its trademark strength and versatility.

Core Components of Corrugated Structure

- Flute: The arched inner layer that provides compression resistance and shock absorption.

- Linerboard: Smooth outer surfaces offering support, printability, and moisture resistance.

- Adhesive: The bonding material that fuses the fluted sheet with the linerboards for stability.

Types of Corrugated Boxes

- Single-Wall: One fluted medium between two liners — ideal for lightweight items and retail packaging.

- Double-Wall: Two fluted layers and three liners — provides extra durability for heavier or fragile products.

- Triple-Wall: Three fluted mediums and four liners — used for industrial or export packaging where maximum strength is required.

Applications of Corrugated Packaging

Corrugated boxes adapt to virtually every industry:

- E-commerce & Retail: Lightweight, printable, and easy to brand for customer appeal.

- Food & Beverage: With protective coatings, they ensure hygienic and secure transport.

- Electronics: Provide anti-shock cushioning for delicate components.

- Industrial & Export: Heavy-duty triple-wall boxes are built for bulk shipments and international transit.

Why Choose Corrugated Boxes from Kardboards?

- Strength with Efficiency: High strength-to-weight ratio reduces freight costs without compromising safety.

- Fully Customisable: Choose from various flute types, coatings, print finishes, and branding options.

- Sustainability: Made from renewable and recyclable materials to align with green packaging goals.

- Cost-Effective: Affordable to produce, easy to store, and reusable — perfect for scaling businesses.

Partner with Kardboards

We provide custom corrugated packaging solutions that integrate strength, protection, and premium visual appeal. Whether you need eco-friendly retail boxes, heavy-duty export cartons, or unique branded designs — Kardboards delivers packaging engineered to perform.

Frequently Asked Questions

What are the different flute types used in corrugated boxes?

Common flute types include A, B, C, E, and F flutes — each offering different combinations of cushioning, stacking strength, and print surface quality.

Can corrugated boxes be recycled?

Yes. Corrugated boxes are among the most recyclable packaging materials globally, made primarily from paperboard with high recycled content.

Which is better — single-wall or double-wall?

Single-wall is ideal for lighter products and short-distance shipping. Double-wall offers extra durability for heavier, bulk, or long-distance applications.

Can I print my logo or design on corrugated boxes?

Absolutely. Kardboards offers full custom printing options, including offset, flexo, and digital printing, to align with your brand identity.