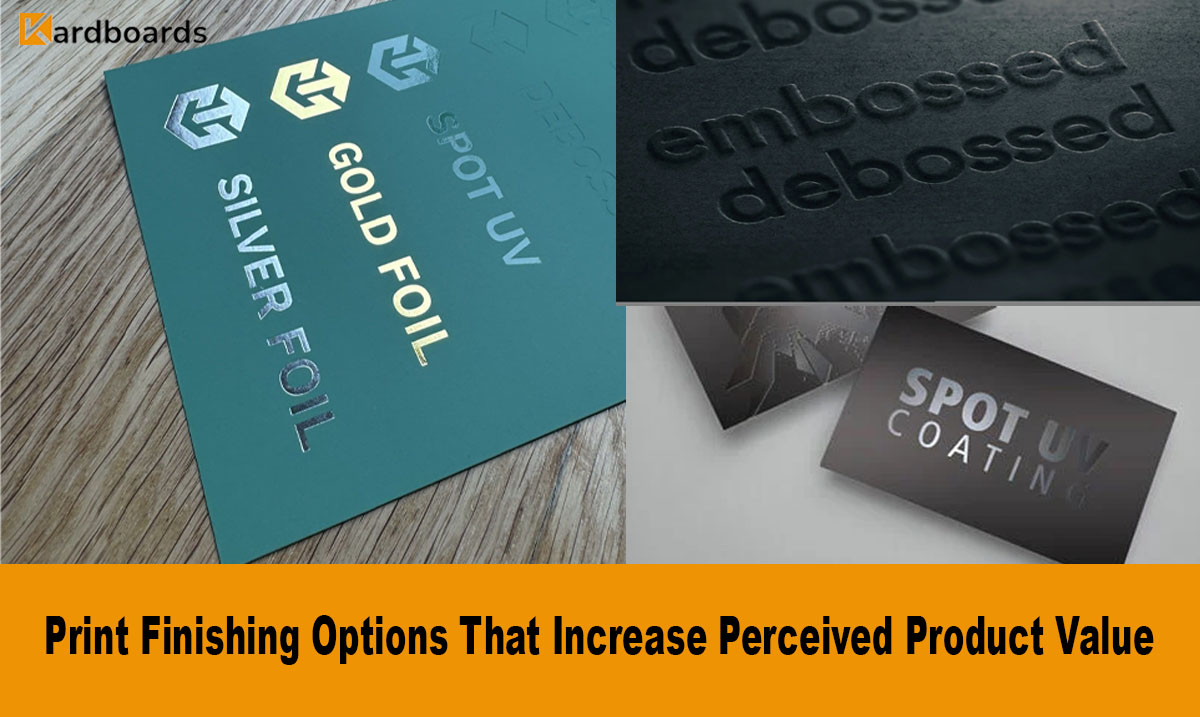

In competitive retail and e-commerce markets, packaging is often the first physical interaction customers have with a brand. Strategic use of print finishing options such as foil stamping, embossing, and debossing can dramatically increase perceived product value, justify premium pricing, and strengthen brand recognition.

Why Print Finishing Matters in Premium Packaging

Beyond color and structure, finishing techniques add sensory appeal that elevates packaging from ordinary to luxurious.

- Creates tactile and visual differentiation

- Signals quality and craftsmanship

- Enhances shelf impact and unboxing experience

- Improves brand recall and trust

Consumer Insight: Customers subconsciously associate textured and reflective finishes with higher product quality.

Foil Stamping Printing: Luxury Through Shine

Foil stamping printing applies metallic or pigmented foil to specific design elements using heat and pressure.

- Common foils: gold, silver, holographic, matte, and colored foils

- Ideal for logos, brand names, and accents

- Works exceptionally well on rigid and luxury boxes

- Provides excellent contrast against matte backgrounds

Foil stamping instantly communicates exclusivity and is widely used in cosmetics, electronics, spirits, and luxury gifting.

Embossing: Creating Raised Brand Elements

Embossing raises specific areas of the packaging surface to create a three-dimensional effect.

- Adds tactile depth without ink or color changes

- Highlights logos, patterns, and typography

- Can be combined with foil stamping for premium impact

- Enhances brand recognition through touch

Design Tip: Minimalist designs benefit most from embossing, allowing texture to become the focal point.

Debossing: Subtle Elegance and Refinement

Debossing presses design elements into the surface, creating an indented effect.

- Offers a refined, understated premium look

- Ideal for luxury stationery and high-end packaging

- Pairs well with soft-touch laminations

- Effective for brands seeking subtle sophistication

Additional Print Finishing Options

Beyond embossing and foil, several other finishes increase perceived value:

- Spot UV coating: Gloss highlights on matte surfaces

- Soft-touch lamination: Velvet-like tactile feel

- Matte and gloss varnishes: Visual contrast and protection

- Texture coatings: Linen, leather, or sand-like effects

Choosing the Right Finish for Your Brand

The best finishing option depends on brand positioning, target audience, and budget.

Strategic Balance: Combining 1–2 premium finishes often delivers stronger impact than overusing multiple techniques.

- Luxury brands benefit from foil and embossing combinations

- Minimalist brands prefer debossing and matte finishes

- E-commerce packaging should balance durability and aesthetics

- Cost-efficiency improves with thoughtful design planning

How Kardboards Delivers Premium Print Finishing

Kardboards integrates advanced finishing capabilities with strict quality control:

- Precision foil stamping and multi-level embossing

- Consistent results across large production runs

- Expert guidance on finish selection and feasibility

- Compatibility with sustainable substrates

- Export-ready quality for US and global markets

Frequently Asked Questions

Does foil stamping increase packaging costs?

Yes, but it significantly enhances perceived value and brand appeal.

Can embossing and debossing be combined?

Yes, combining both techniques creates depth and visual hierarchy.

Are finishing techniques durable for shipping?

When properly applied, premium finishes withstand handling and transit.

Which finish is best for minimalist brands?

Debossing and soft-touch laminations are ideal for subtle elegance.

Is sustainable packaging compatible with premium finishes?

Yes, many finishing techniques work with FSC-certified and eco-friendly materials.