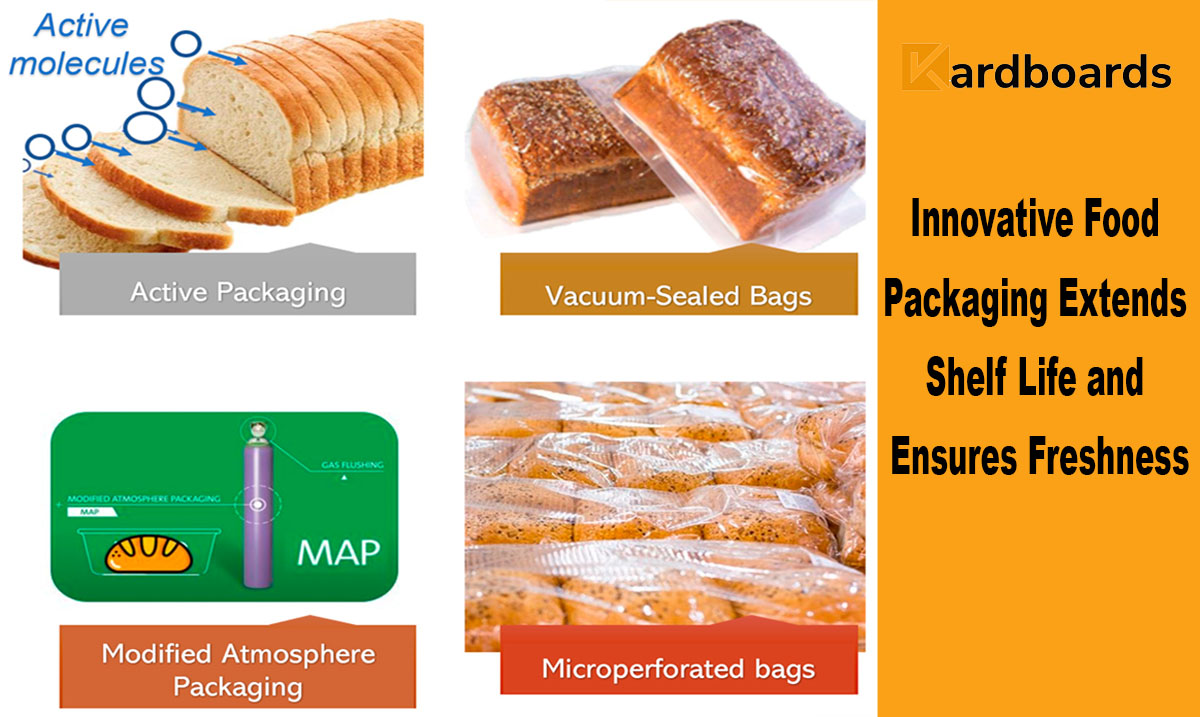

Food freshness is no longer just about temperature control — packaging now plays a leading role. Modern packaging is engineered to protect food from oxygen, moisture, bacteria, light exposure, and handling during storage and transport. With innovations like MAP, barrier films, and intelligent indicators, brands can now significantly extend product shelf life while reducing waste and improving safety.

1. Modified Atmosphere Packaging (MAP): The Industry Standard for Freshness

MAP replaces the natural air inside a package with a controlled gas mixture such as nitrogen or carbon dioxide. This slows bacterial growth and oxidation.

- Ideal for: meats, bakery products, fresh produce, ready-to-eat meals.

- Benefits: extends shelf life, preserves color and texture, reduces food waste.

- Flexible gas ratios: optimized per product type to maximize life.

2. High-Barrier Films: Protection Against Oxygen & Moisture

Advanced multilayer films keep air and humidity out while sealing in freshness. They are essential for sensitive foods.

- Aluminum-based barriers protect against light and oxygen.

- EVOH-layer films prevent oxygen permeation while remaining lightweight.

- Bio-based barriers are emerging for eco-conscious brands.

3. Active Packaging: Packaging That Interacts to Slow Spoilage

Active packaging contains elements that actively improve food safety and freshness.

- Oxygen absorbers: prevent oxidation in snacks and baked goods.

- Moisture absorbers: prevent sogginess in produce and fried foods.

- Ethylene absorbers: slow ripening of fruits and vegetables.

4. Intelligent & Smart Packaging: Real-Time Freshness Monitoring

Smart packaging uses sensors and indicators to show the condition of the food.

- Time–temperature indicators: show if cold-chain conditions were compromised.

- Freshness indicators: change color when spoilage begins.

- QR authentication: ensures traceability and consumer trust.

5. Vacuum Packaging: A Proven Method for Oxygen-Sensitive Products

By removing air completely, vacuum packaging dramatically slows microbial growth.

- Best for: meat, seafood, dried foods, cheese.

- Improves flavor retention by minimizing oxidation.

- Reduces freezer burn for frozen products.

6. Antimicrobial Packaging: Enhanced Safety Through Science

Some packaging materials are infused with antimicrobial agents that inhibit bacterial growth.

- Silver ions—effective against pathogens.

- Natural extracts like oregano or rosemary for clean-label brands.

- Biodegradable antimicrobial films for sustainability-focused markets.

Key takeaway: Combining barrier materials, MAP, and smart indicators can extend shelf life by 30–300% depending on the food type.

Frequently Asked Questions

Does MAP packaging really extend shelf life?

Yes. MAP slows oxidation and bacterial growth by controlling the gas mixture inside the package, making it one of the most effective shelf-life extension methods.

What foods benefit the most from vacuum packaging?

Meat, fish, nuts, dried fruits, and cheese benefit significantly due to reduced oxygen exposure.

Is smart packaging expensive?

The cost varies, but many brands adopt low-cost time–temperature indicators for cold-chain products. Costs are falling as adoption grows.

Are antimicrobial packaging materials safe?

Yes. They are regulated and tested for food safety. Natural antimicrobial films are also widely accepted.

What’s the biggest factor that reduces food freshness?

Oxygen exposure is the leading cause, followed by moisture imbalance, light exposure, and improper temperature handling.