At Kardboards, folding box production is more than just packaging — it’s a carefully engineered process designed to enhance your brand’s presentation and product safety. Our folding cartons combine durability, functionality, and aesthetics to meet the demands of industries ranging from cosmetics and electronics to food and luxury retail.

By integrating innovative printing technologies, sustainable materials, and rigorous quality control, we deliver packaging that not only protects but also communicates your brand’s value and identity.

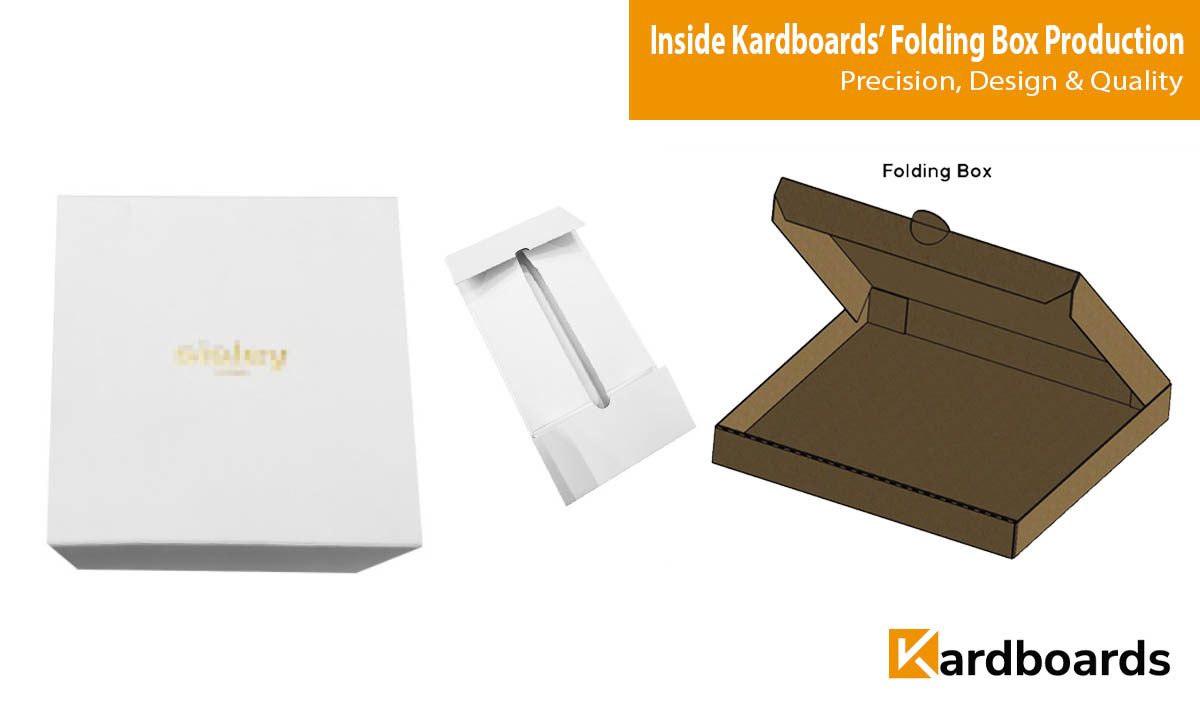

The Anatomy of a Folding Box

A folding box, also known as a folding carton, is made from paperboard that is printed, laminated, cut, creased, and folded into shape. These boxes are lightweight yet strong, offering design flexibility and cost-effectiveness.

- Material: Typically crafted from high-grade SBS (Solid Bleached Sulfate) or recycled paperboard for smooth print surfaces.

- Structure: Custom die-cut panels and locking mechanisms for easy assembly and secure closure.

- Finish: Available with gloss, matte, or soft-touch coatings and optional foil stamping or embossing.

Our Production Process

Kardboards’ production line is powered by precision machinery and skilled craftsmanship at every stage:

- Design & Structural Engineering: Our experts develop dielines and prototypes ensuring perfect product fit and functionality.

- Printing: Using advanced offset, digital, or flexographic printing to achieve vivid, consistent results on various paperboard types.

- Coating & Finishing: Protective layers such as UV coating, matte lamination, or aqueous varnish are added for visual appeal and durability.

- Die Cutting & Creasing: High-precision machines create exact cuts and folds to ensure smooth assembly.

- Folding & Gluing: Automated gluing lines maintain perfect alignment and bonding strength for high-speed production.

- Inspection & Packaging: Every batch undergoes strict quality control for alignment, print accuracy, and finish integrity.

Why Kardboards Folding Boxes Stand Out

- Customizable Designs: From structural layout to visual finishes, every box is built around your brand’s needs.

- Advanced Printing Quality: Crisp colors, precision registration, and eco-friendly inks for vibrant presentation.

- Sustainable Production: FSC-certified paperboards, water-based coatings, and recyclable materials for eco-responsible packaging.

- Cost-Efficient Manufacturing: Optimized processes minimize waste and ensure consistent, on-time delivery.

Applications Across Industries

Folding boxes are adaptable across multiple product categories:

- Cosmetics & Beauty: Elegant folding cartons that enhance retail shelf presence.

- Food & Beverage: Safe, printed cartons suitable for direct and indirect food contact.

- Electronics: Protective yet sleek designs that showcase technology with style.

- Luxury Products: Premium finishes such as foil embossing and spot UV for a refined unboxing experience.

Frequently Asked Questions

What materials are used in folding box production?

Folding boxes are typically made from paperboard — including SBS, CUK (Coated Unbleached Kraft), or recycled options — depending on product weight and sustainability goals.

Are folding boxes eco-friendly?

Yes. Kardboards focuses on eco-friendly materials and coatings that are recyclable and biodegradable, aligning with global sustainability standards.

Can folding boxes be customized for luxury branding?

Absolutely. We offer custom shapes, magnetic closures, foil stamping, embossing, and matte or gloss finishes for premium product lines.

How does Kardboards ensure print accuracy?

Our automated color management systems and offset printing technology ensure precise color consistency across every batch.

Do you provide prototypes or samples before production?

Yes. Kardboards provides dieline mockups and printed samples to confirm design and fit before mass production.