When working with an overseas packaging supplier, one of the most important planning factors for US buyers is the packaging lead time. Lead times impact production schedules, inventory planning, promotional campaigns, and ultimately, customer satisfaction. This article breaks down what US brands should anticipate when coordinating with manufacturers abroad.

What Is Packaging Lead Time?

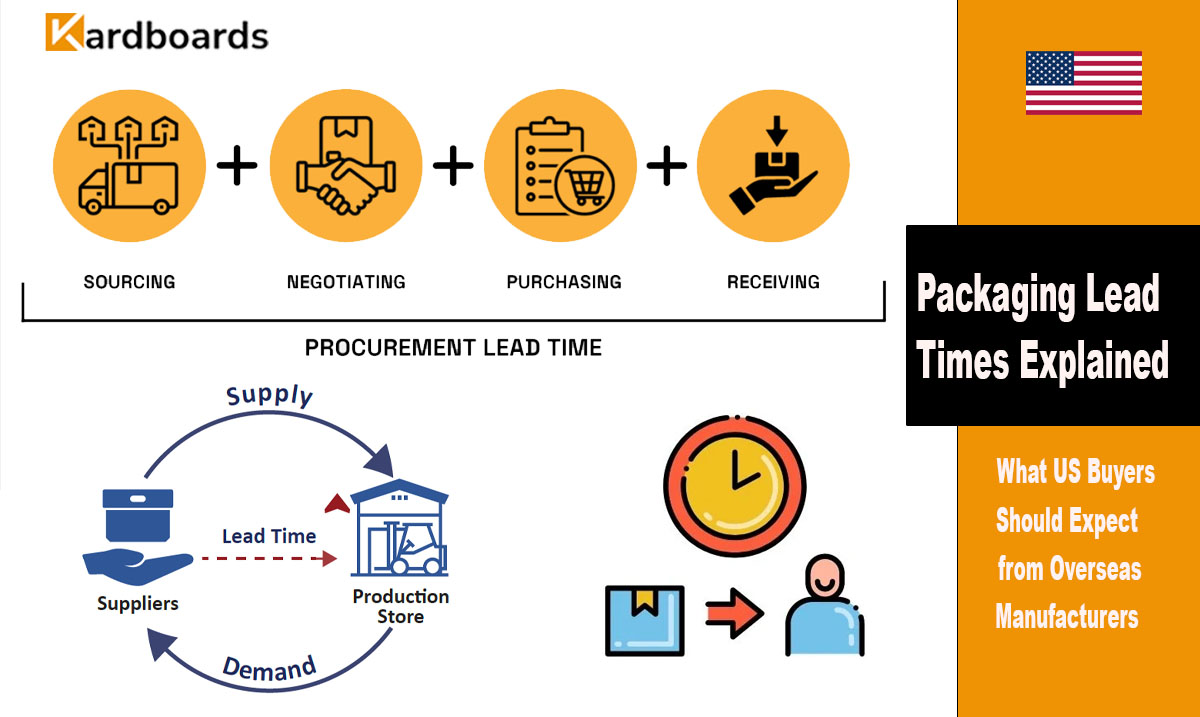

Packaging lead time refers to the total time required from the moment an order is confirmed until the packaging products are ready for shipment. It includes design approval, sampling, production, quality control, and export logistics.

- Quotation and design confirmation

- Sampling and prototyping

- Mass production timelines

- Inspection and quality assurance

- Export documentation and port handling

Typical Lead Time Components

Understanding typical time components helps buyers plan effectively:

- Design & Proofing: 3–7 business days

- Sampling: 7–14 days depending on complexity

- Mass Production: 14–30+ days based on order size and printing requirements

- Inspection: 1–3 days

- Export & Shipping Prep: 3–7 days before vessel departure

Note: These are typical timelines — seasonal demand, material shortages, and customizations can influence lead times significantly.

Factors Influencing Packaging Lead Times

Several variables affect how long production and delivery will take:

- Order Quantity: Larger volumes require more production runs.

- Customization Level: Complex designs and finishes add time.

- Material Availability: Specialty substrates can delay schedules.

- Seasonal Peaks: Holidays and trade events increase demand.

- Quality Inspections: Additional checks lengthen timelines but ensure quality.

How Overseas Packaging Suppliers Manage Timelines

Experienced manufacturers like Kardboards streamline production timelines with structured processes:

- Pre-production planning and digital proofs

- Standardized sampling workflows

- Automated production lines for consistency

- Staggered scheduling to optimize capacity

Tips for US Buyers to Reduce Lead Time Delays

Proactive planning helps minimize unexpected delays:

- Confirm Specs Early: Provide finalized artwork and specifications before order placement.

- Approve Samples Promptly: Quick feedback accelerates production starts.

- Plan Around Peaks: Avoid ordering near major holidays or factory shutdown periods.

- Communicate Regularly: Maintain clear communication with your supplier.

Why Lead Times Matter for US Buyers

Packaging lead times directly impact business operations:

- Inventory Management: Prevent stockouts with accurate scheduling.

- Marketing Campaigns: Ensure packaging arrives before product launches.

- Cash Flow Planning: Timely shipments optimize working capital.

- Customer Satisfaction: On-time deliveries build brand reliability.

Frequently Asked Questions

What is a typical packaging lead time?

A typical packaging lead time can range from 4–8 weeks from order confirmation to shipment ready.

Can lead times vary by supplier?

Yes. Each overseas packaging supplier has workflows, capacity, and materials that affect timing.

Does customization extend lead times?

Yes. More complex designs, finishes, and materials typically require longer production times.

How can US buyers track progress?

Regular updates, sample approvals, and production photos help buyers stay informed throughout the timeline.

Does shipping time count in lead time?

Shipping is usually separate from the production lead time, but it's essential for overall delivery planning.