In competitive premium markets, packaging is more than protection—it is a silent brand ambassador. Specialty printing and advanced finishing techniques play a critical role in elevating packaging from ordinary to extraordinary, shaping customer perception and reinforcing brand value.

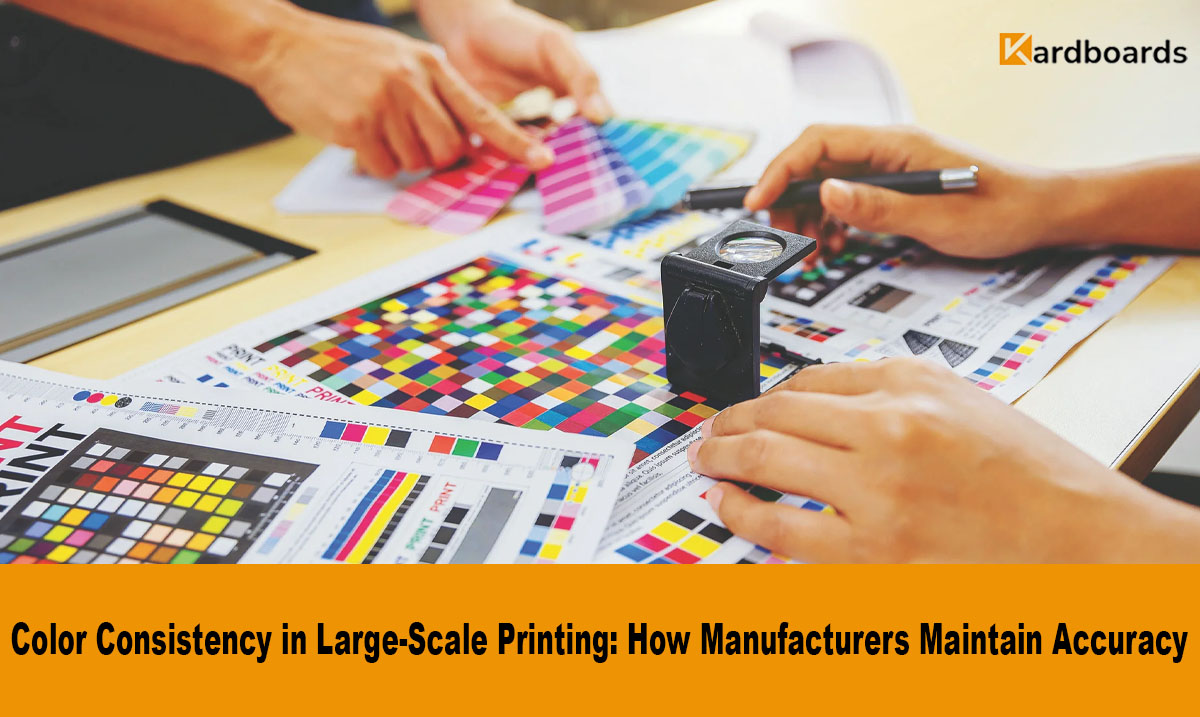

What Are Specialty Printing Techniques?

Specialty printing refers to advanced printing and finishing processes applied after or alongside standard offset or digital printing. These techniques add texture, depth, shine, and tactile appeal, creating a multi-sensory unboxing experience.

Luxury Insight: Premium consumers associate tactile and visual detail with higher product quality.

Foil Stamping: Metallic Elegance

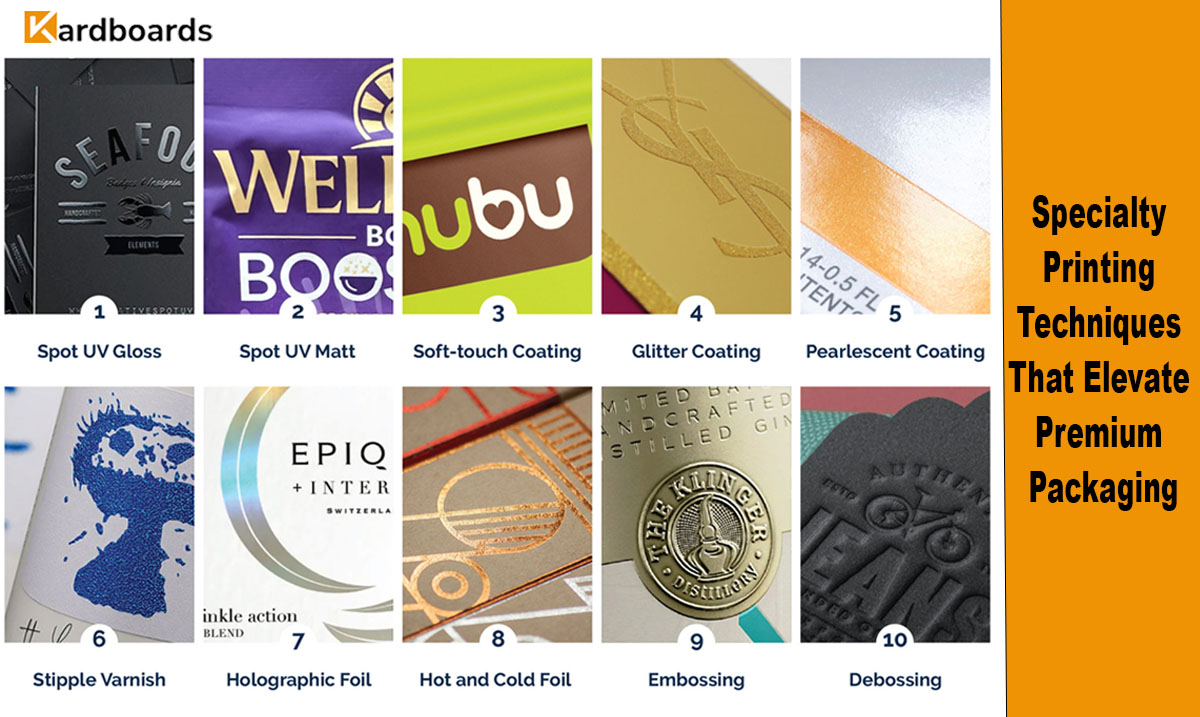

Foil stamping applies metallic or pigmented foil to packaging surfaces using heat and pressure. It is widely used in luxury packaging to highlight logos, borders, and typography.

- Gold, silver, rose gold, holographic foils

- Sharp contrast against matte backgrounds

- High perceived value and brand prestige

Embossing & Debossing: Texture That Speaks

Embossing raises design elements, while debossing presses them inward. These techniques create tactile depth that enhances brand memorability.

- Ideal for logos and brand marks

- Subtle, elegant luxury effect

- Often combined with foil stamping

Spot UV Coating: Controlled Brilliance

Spot UV applies a glossy coating to specific areas of the packaging, creating contrast between matte and glossy surfaces.

Visual Impact: Spot UV naturally draws the eye to logos, icons, and key design elements.

- Enhances depth and contrast

- Works well with dark or matte finishes

- Common in cosmetics and electronics packaging

Soft-Touch & Matte Lamination

Soft-touch lamination delivers a velvet-like feel, while matte lamination reduces glare and enhances sophistication.

- Premium tactile experience

- Fingerprint resistance

- Often paired with foil or embossing

Textured & Specialty Inks

Luxury printing techniques extend beyond finishes to include specialty inks that add character and distinction.

- Pearlescent and metallic inks

- Thermochromic (color-changing) inks

- Raised UV and textured varnishes

Die-Cutting & Structural Enhancements

Precision die-cutting enables unique shapes, windows, and layered effects that elevate packaging structure alongside print finishes.

Design Advantage: Structural creativity combined with specialty printing delivers maximum shelf impact.

How Specialty Printing Elevates Brand Perception

Premium print finishing influences how consumers emotionally connect with a brand.

- Signals quality and craftsmanship

- Builds trust in premium pricing

- Enhances unboxing experiences

- Encourages social sharing and brand recall

Choosing the Right Specialty Printing Techniques

Not every luxury finish suits every brand. Selection should consider product type, audience expectations, and budget.

- Minimalist brands benefit from subtle embossing

- Luxury gifting favors foil and soft-touch finishes

- Tech and beauty brands often use spot UV contrasts

How Kardboards Delivers Premium Print Finishing

Kardboards integrates advanced luxury printing techniques with precise quality control:

- In-house foil stamping and embossing units

- High-precision registration for complex finishes

- Material and finish compatibility testing

- Export-ready quality for global brands

Frequently Asked Questions

Are specialty printing techniques expensive?

They add cost, but significantly increase perceived product value and brand impact.

Can specialty printing be combined?

Yes. Foil stamping, embossing, and spot UV are often combined for layered luxury effects.

Do luxury finishes affect recyclability?

Some finishes may impact recyclability, but eco-friendly alternatives are increasingly available.

Is specialty printing suitable for small batches?

Some techniques are better suited for larger volumes, while others can be adapted for short runs.

Which industries benefit most from specialty printing?

Cosmetics, luxury retail, electronics, fashion, and premium gifting brands benefit the most.