Strip packaging is a type of flexible packaging commonly used for unit-dose items such as tablets, capsules, and small hardware components. The design involves sealing products between two layers of film — typically aluminum foil, plastic laminate, or paper — using heat or pressure. This method ensures airtight protection and precise individual packaging for sensitive or high-value products.

At Kardboards, we specialize in developing custom strip packaging solutions optimized for durability, moisture resistance, and aesthetic presentation, catering to industries across healthcare, consumer electronics, and personal care.

Understanding Strip Packaging Design

Strip packs consist of a product enclosed between two flexible materials that are heat-sealed along all edges. Unlike blister packs — which have pre-formed cavities — strip packs form directly around the product, creating a smaller, space-efficient packaging unit.

- Materials Used: Aluminum foil, PVC, PET, paper laminate, or biodegradable films.

- Sealing Mechanism: Heat, cold, or ultrasonic sealing ensures airtight protection.

- Printing: Surface printing for batch codes, dosage details, or branding elements.

Did you know? Strip packaging is often preferred for moisture-sensitive pharmaceuticals since it offers better barrier protection than traditional blister packaging.

Advantages of Strip Packaging

- Superior Barrier Protection: Prevents contamination, moisture ingress, and oxidation.

- Cost-Efficient: Requires less material than rigid packaging formats.

- Portable and Lightweight: Ideal for unit-dose medicines or compact consumer products.

- Printable Surface: Supports brand logos, regulatory data, and QR codes.

- Extended Shelf Life: Airtight seals help maintain product integrity for longer durations.

- Sustainability Options: Use of recyclable and biodegradable laminates reduces environmental impact.

Applications Across Industries

Although strip packaging is primarily known for its use in the pharmaceutical sector, it also serves a range of industrial and consumer markets:

- Pharmaceuticals: Tablets, capsules, and oral strips for accurate dosage and contamination prevention.

- Electronics: Small components, resistors, and sensors sealed for dust-free handling.

- Personal Care: Wet wipes, single-use creams, or cosmetic samples in strip sachets.

- Food & Nutrition: Dietary supplements, coffee sachets, and seasoning portions.

Kardboards’ Expertise in Strip Packaging

Kardboards integrates precision engineering, quality control, and custom printing to deliver strip packaging that meets international manufacturing and regulatory standards.

- High-speed automated sealing lines for consistent production quality.

- Custom lamination structures designed for specific barrier and visual requirements.

- Support for eco-friendly packaging using recyclable aluminum or bio-films.

- Regulatory-compliant labeling for pharmaceuticals and medical devices.

Innovation meets protection: Kardboards’ R&D focuses on hybrid paper-aluminum laminates that combine sustainability with industrial performance.

Frequently Asked Questions

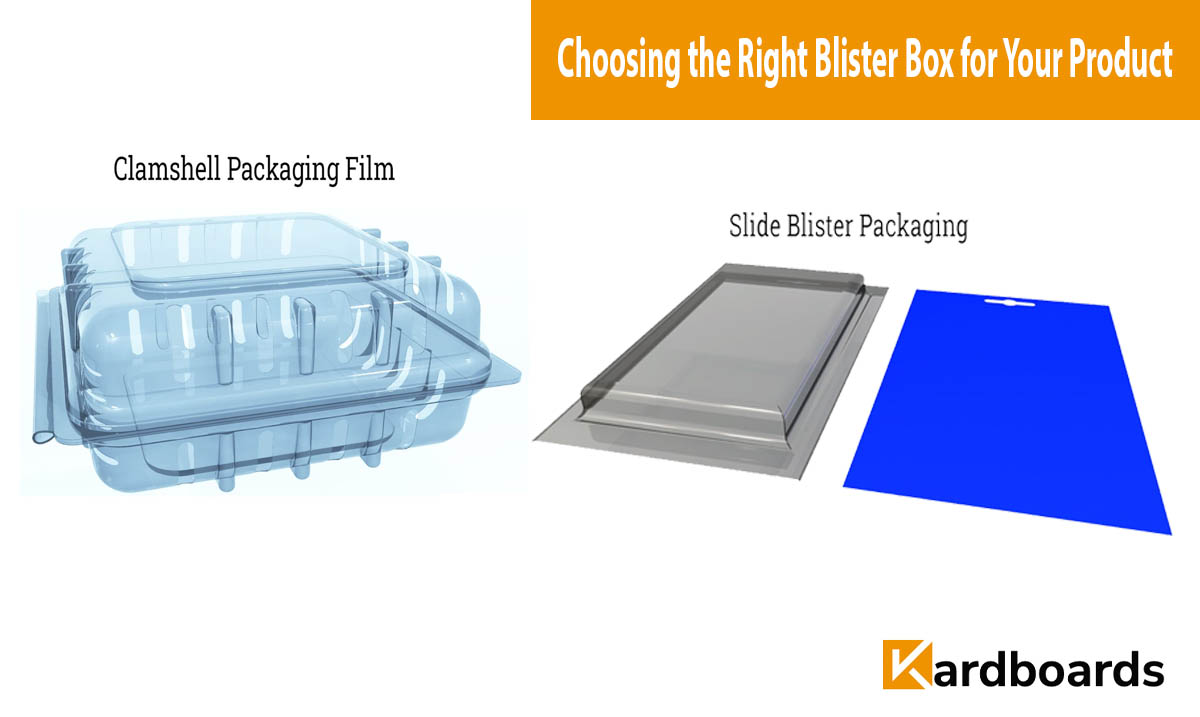

What is the difference between blister and strip packaging?

Blister packs use pre-formed cavities made from plastic and sealed with foil, while strip packs seal the product directly between two layers of material, making them more compact and barrier-effective.

Which materials are best for strip packaging?

Common materials include aluminum foil, PET film, PVC, and biodegradable paper-based laminates, chosen based on product sensitivity and shelf-life needs.

Is strip packaging suitable for food products?

Yes, it is used for small portioned items such as coffee, sugar, or seasoning sachets, offering freshness and easy dispensing.

Can strip packaging be recycled?

Depending on the material composition, many strip packs are recyclable or available in sustainable bio-film variants developed by Kardboards.

Does Kardboards offer custom printed strip packaging?

Absolutely. Kardboards provides custom printing, lamination finishes, and branding options for both pharmaceutical and consumer applications.