Behind every reliable package is thoughtful packaging engineering. While graphics attract customers, it is structural design that ensures products arrive intact from factory to end user.

Effective box structure design balances strength, efficiency, material use, and cost. For global brands shipping across long distances, structural packaging is not optional—it is essential.

What Is Structural Packaging Design?

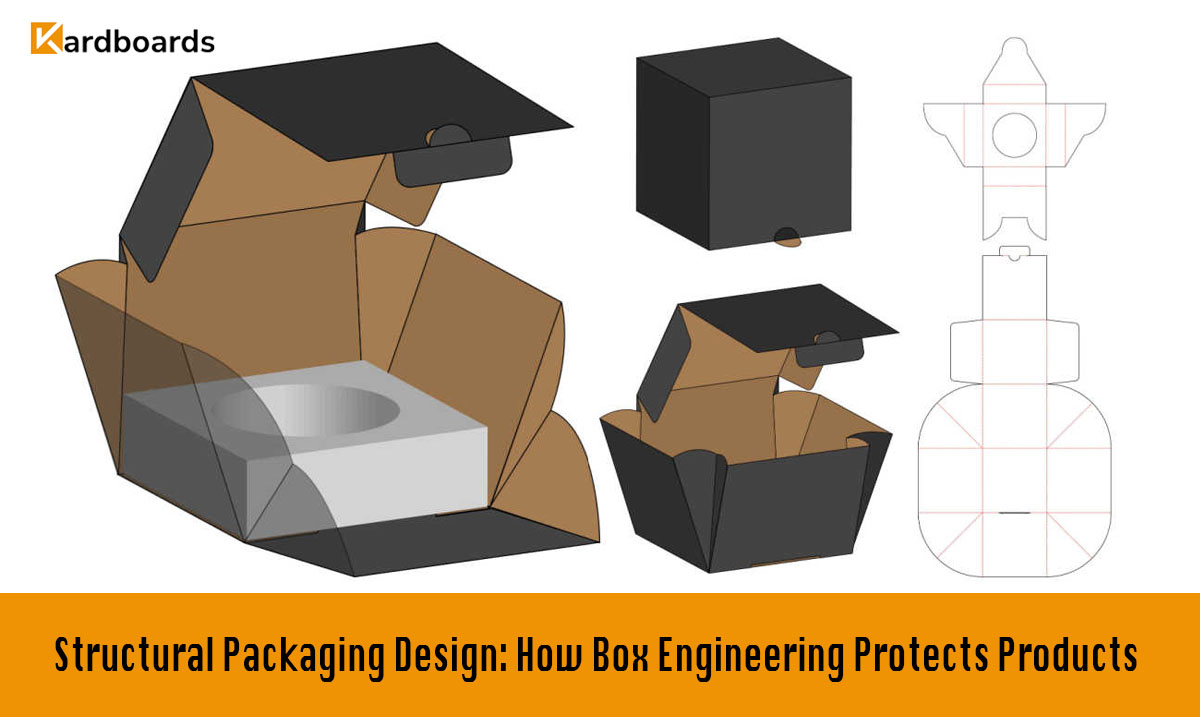

Structural packaging design focuses on the physical construction of a box rather than its visual appearance.

- Box geometry and load distribution

- Material thickness and flute selection

- Internal supports, inserts, and partitions

- Ease of assembly and stacking performance

Engineering Insight: A well-designed structure can reduce material usage while improving protection.

How Box Engineering Protects Products

Protective box design works by managing external forces applied during transport.

- Compression resistance: Prevents collapse under stacking loads

- Shock absorption: Minimizes impact damage from drops

- Vibration control: Reduces wear during long-distance shipping

- Secure fit: Prevents product movement inside the box

Key Structural Elements in Protective Box Design

Each component plays a specific role in product safety.

- Double-wall and triple-wall corrugated boards

- Reinforced corners and edges

- Die-cut inserts and molded trays

- Suspension and floating packaging systems

Best Practice: Structural reinforcement should target stress points rather than increasing overall material thickness.

Matching Structure to Product Type

Not all products require the same level of protection.

- Electronics require anti-shock and anti-static designs

- Glass and ceramics need rigid support and cushioning

- Luxury goods demand precision-fit rigid boxes

- Industrial products need heavy-duty corrugated structures

Structural Design and Cost Efficiency

Well-engineered packaging reduces total cost of ownership.

- Lower damage and return rates

- Reduced material waste

- Optimized pallet utilization

- Lower shipping and storage costs

Structural optimization often delivers better savings than simply switching to cheaper materials.

Testing and Validation in Packaging Engineering

Professional packaging engineering relies on testing, not assumptions.

- Drop and impact testing

- Compression and stacking tests

- Vibration simulation

- Environmental condition testing

Structural Packaging for Global Shipping

International shipping introduces multiple handling points and transport modes.

Export-ready protective box design accounts for container stacking, humidity changes, long transit times, and regulatory requirements.

Frequently Asked Questions

What is packaging engineering?

Packaging engineering focuses on designing box structures that protect products efficiently.

How does box structure design prevent damage?

By managing impact, compression, and movement during shipping and handling.

Is protective packaging expensive?

Not necessarily. Proper structural design often reduces overall costs by preventing damage.

Can structural packaging be customized?

Yes. Box structures can be engineered to match product size, weight, and fragility.

Does structural design affect sustainability?

Yes. Efficient structures use less material and reduce waste and shipping emissions.