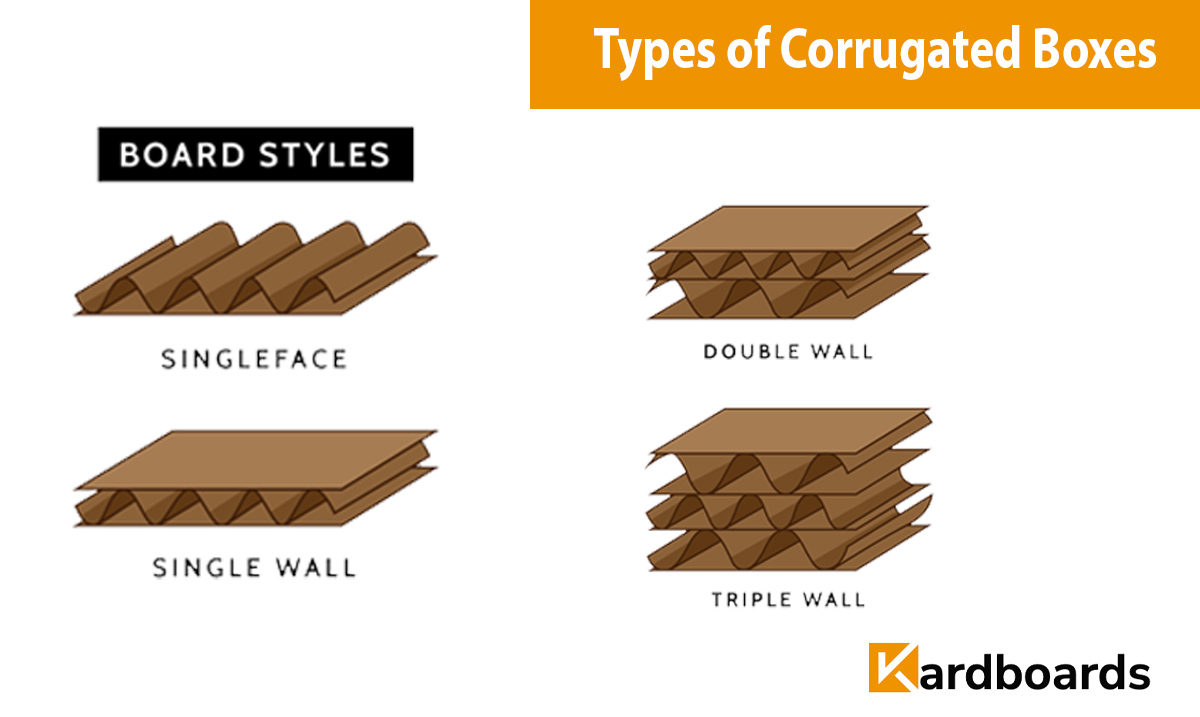

Corrugated boxes are the backbone of global logistics and retail packaging. They provide unmatched durability, lightweight structure, and cost-effective protection. But not all corrugated boxes are built the same — the difference lies in their wall construction, flute type, and intended application. This guide by Kardboards explains every type of corrugated box, helping brands and businesses make informed packaging choices.

1. Single Wall Corrugated Boxes

The most common type, single wall boxes are made from one layer of fluted paper sandwiched between two linerboards. They’re suitable for general shipping, e-commerce, and lightweight goods.

- Used for: Retail packaging, electronics, food, cosmetics

- Advantages: Economical, lightweight, recyclable

- Flute Types: A, B, C, E, and F

2. Double Wall Corrugated Boxes

Double wall boxes feature two fluted mediums and three liners for superior strength. They provide added protection for fragile or heavier products during long-distance shipping.

- Used for: Home appliances, industrial tools, furniture

- Advantages: Extra cushioning, puncture resistance, stackability

- Common Flute Combinations: BC, EB, or AC

3. Triple Wall Corrugated Boxes

Built for maximum strength, triple wall boxes are often referred to as “corrugated wood.” With three flutes and four liners, they are used for heavy-duty exports and bulk transport of industrial goods.

- Used for: Machinery, automotive parts, metal components

- Advantages: Extremely durable, replaces wooden crates

- Common Flute Combinations: ABC or BAA

Triple wall boxes offer a compressive strength of up to 1000 kg — ideal for sea freight and warehouse stacking.

4. Corrugated Box Styles and Designs

| Box Style | Description | Typical Use |

|---|---|---|

| Regular Slotted Container (RSC) | Most standard type with flaps meeting at the center. | General shipping, storage boxes |

| Half Slotted Container (HSC) | Open-top design for easy loading and unloading. | Warehouse storage, retail display |

| Full Overlap Box (FOL) | Flaps fully overlap, offering extra cushioning on top and bottom. | Heavy goods, fragile products |

| Die-Cut Boxes | Custom shapes with precision cuts for branding and aesthetics. | Consumer packaging, e-commerce |

| Telescopic Boxes | Two-piece structure with a lid and base. | Luxury packaging, electronics |

5. Understanding Flute Types

Flutes are the wavy layers that give corrugated boxes their strength and cushioning. Each flute type offers unique benefits for thickness, compression strength, and print quality.

- A Flute: 5mm thick — excellent cushioning and stacking.

- B Flute: 3mm thick — strong puncture resistance.

- C Flute: 4mm thick — versatile and most common.

- E Flute: 1.5mm thick — sleek and suitable for printing.

- F Flute: 1mm thick — used in micro-flute retail packaging.

6. Sustainable Corrugated Solutions by Kardboards

At Kardboards, sustainability and innovation go hand in hand. All corrugated boxes are manufactured using FSC-certified paper, water-based inks, and recyclable adhesives. Kardboards also provides custom flute combinations to optimize performance while reducing material use.

The company exports millions of boxes annually to Europe, the USA, and Asia, supporting brands in e-commerce, logistics, food, and industrial sectors.

Frequently Asked Questions

Which corrugated box type is best for export packaging?

Triple wall corrugated boxes are the most durable choice for export shipments and industrial freight due to their superior compression strength.

Can single wall boxes handle heavy products?

They are suitable for light to moderate weight items. For heavier loads, double wall or reinforced single wall options are better.

What’s the difference between flute types?

Flutes determine the box’s strength and print quality — larger flutes (A, B) offer cushioning, while smaller flutes (E, F) give smoother surfaces for printing.

Are corrugated boxes environmentally friendly?

Yes. Corrugated boxes are 100% recyclable, biodegradable, and made from renewable resources like kraft paper and starch-based adhesives.