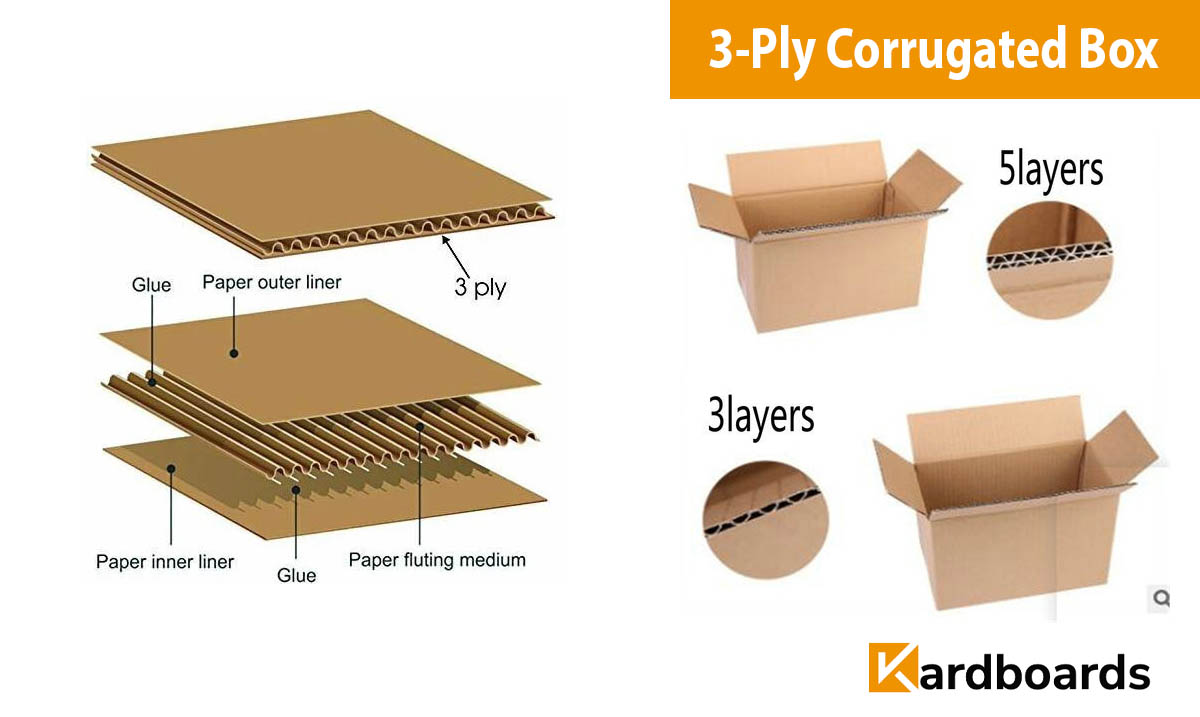

A 3-ply corrugated box is one of the most common and versatile packaging solutions used across industries. It consists of three layers — two flat outer sheets called linerboards and one inner wavy sheet known as the fluted medium. This design provides strength, cushioning, and resistance to compression while remaining lightweight and eco-friendly.

At Kardboards, we engineer 3-ply corrugated boxes using premium kraft paper and precision corrugation techniques to ensure consistent quality, durability, and sustainability — suitable for both domestic and export packaging applications.

Structure of a 3-Ply Corrugated Box

The term "3-ply" refers to the total number of paper layers:

- Top Liner: The outer surface that can be printed, laminated, or coated for branding and moisture resistance.

- Fluted Medium: The central wavy layer that gives the box its rigidity, cushioning, and stacking strength.

- Bottom Liner: The inner surface that provides base support and structural balance.

Common flute types used in 3-ply boxes include E-flute (for small retail packaging), B-flute (for standard shipping cartons), and C-flute (for heavy-duty packaging). The choice of flute depends on the product’s weight, fragility, and shipping conditions.

Material and Paper Grades

3-ply corrugated boxes are generally made from kraft paper with GSM ranging from 120 to 200, depending on load-bearing needs. Kardboards offers multiple options:

- High-BF Kraft Paper: Ensures better bursting and compression resistance.

- Recycled Linerboard: For eco-conscious brands focusing on sustainability.

- Coated Liners: For moisture and oil resistance in food and cosmetic packaging.

We also provide water-based adhesives and soy inks to maintain eco-friendly standards and meet export regulations for sustainable packaging.

Applications of 3-Ply Corrugated Boxes

- Retail & E-commerce: Perfect for shipping lightweight to medium-weight products.

- Food Delivery & FMCG: Used for packaging processed foods, bakery, and takeaway meals.

- Electronics & Household Items: Protects fragile products during storage and transport.

- Cosmetics & Healthcare: Offers clean, printable surfaces for branding and labeling.

Due to its balance of strength and economy, the 3-ply corrugated box remains the backbone of global retail and logistics packaging.

Comparison: 3-Ply vs. 5-Ply vs. 7-Ply Boxes

- 3-Ply: Ideal for lightweight to medium-weight packaging — best for retail and e-commerce.

- 5-Ply: Two fluted mediums and three liners — stronger, used for heavier products and stacking.

- 7-Ply: Industrial-grade strength for exports, machinery, and bulk shipments.

Each ply level adds strength, stability, and protection, allowing Kardboards to design customized packaging solutions for diverse product categories.

Why Choose Kardboards 3-Ply Corrugated Boxes?

- Precision Manufacturing: Automated flute forming and uniform adhesion for superior quality.

- Customizable Options: Print, die-cut, laminate, or emboss to match your branding goals.

- Eco-Friendly Production: 100% recyclable and biodegradable paper-based materials.

- Cost-Effective: Light in weight yet durable — saving on shipping costs and storage space.

Frequently Asked Questions

What GSM paper is used in a 3-ply corrugated box?

Typically, 3-ply boxes use kraft paper between 120–200 GSM depending on the box’s load capacity and purpose.

How strong is a 3-ply corrugated box?

It can safely carry 2–10 kg of weight, depending on the flute type, GSM, and manufacturing quality. Kardboards’ boxes are tested for high compression and bursting strength.

Is a 3-ply box suitable for export packaging?

While ideal for domestic and retail use, exports often require 5-ply or 7-ply boxes for added durability. However, lightweight exports can still use reinforced 3-ply boxes.

Are 3-ply corrugated boxes eco-friendly?

Yes. Made from renewable paper fibers, they are fully recyclable, biodegradable, and compliant with global environmental standards.

Can I get custom-printed 3-ply boxes from Kardboards?

Absolutely. Kardboards provides full-color printing, branding finishes, and structural customization to align with your brand image and product requirements.