For global brands and importers, understanding custom packaging pricing is essential for accurate budgeting and supplier selection. Unlike off-the-shelf boxes, custom packaging costs are influenced by multiple variables—from materials and printing to logistics and compliance. This guide explains the most important packaging cost factors that shape international packaging costs.

Why Custom Packaging Pricing Varies

Custom packaging is not a fixed-price product. Each project is engineered to specific dimensions, materials, and branding requirements.

- Unique box size and structure

- Material grade and thickness

- Printing complexity and finishes

- Order volume and production efficiency

Key Insight: Two boxes that look similar can have very different costs due to hidden production variables.

Material Selection: The Primary Cost Driver

Materials account for a significant portion of custom packaging pricing.

- Paperboard and corrugated packaging for cost efficiency

- Rigid boxes and MDF structures for premium products

- Eco-friendly and FSC-certified materials at a moderate premium

- Protective inserts and cushioning components

Thicker boards and higher GSM materials increase strength—but also increase cost.

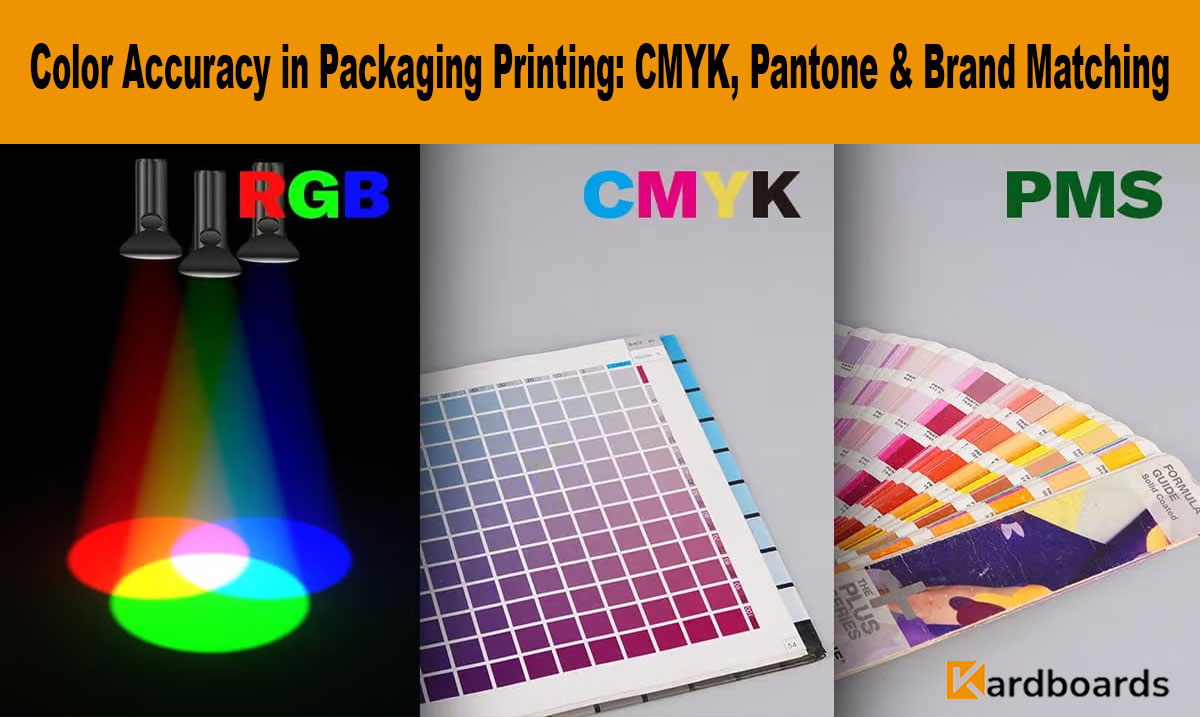

Printing & Finishing Costs

Premium printing and finishing significantly influence final pricing.

- Offset vs digital printing methods

- Number of colors and ink coverage

- Special finishes like foil stamping, embossing, and spot UV

- Lamination type (matte, gloss, soft-touch)

Order Quantity & MOQ Impact

Order volume directly affects unit pricing.

- Higher MOQs reduce per-unit cost

- Low MOQ packaging supports testing but costs more per unit

- Tooling and setup fees are spread across larger quantities

- Hybrid production runs help balance cost and flexibility

Cost Strategy: Scaling quantities strategically can reduce packaging cost by 20–40%.

Tooling, Dies & Setup Fees

One-time setup costs are common in custom packaging projects:

- Cutting dies for box shapes

- Printing plates for offset printing

- Embossing and foil stamping molds

- Prototype and sampling costs

These costs are typically paid once and reused for future orders.

Labor & Manufacturing Location

Manufacturing location plays a role in international packaging costs.

- China offers competitive labor and advanced equipment

- Automation reduces variability and defects

- Experienced packaging engineers improve efficiency

- Quality control labor ensures export readiness

Shipping, Duties & Logistics

International buyers must consider logistics beyond factory pricing.

- Carton size and container utilization

- Sea freight vs air freight costs

- Import duties and customs clearance

- Packaging weight and dimensional volume

Logistics Tip: Optimized box dimensions reduce shipping costs more than most buyers expect.

Compliance & Quality Assurance Costs

Export-ready packaging often includes compliance-related expenses:

- FSC certification and material traceability

- FDA, CPSIA, and EU compliance testing

- Packaging testing and inspection procedures

- Documentation for international shipments

How Kardboards Helps Optimize Packaging Costs

Kardboards works closely with international buyers to balance quality and cost:

- Transparent cost breakdowns

- Material and structure optimization

- Scalable production planning

- Export-focused logistics coordination

This ensures predictable pricing without compromising performance or brand perception.

Frequently Asked Questions

What is the biggest factor in custom packaging pricing?

Material selection and order quantity typically have the largest impact on cost.

Is overseas packaging always cheaper?

Overseas manufacturing can be cost-effective, but logistics and compliance must be considered.

How can I reduce international packaging costs?

Optimize box size, increase order quantity, and simplify printing and finishes.

Are tooling costs a one-time expense?

Yes, most tooling and die costs are paid once and reused for future orders.

Does sustainable packaging cost more?

Eco-friendly materials may cost slightly more, but they support compliance and brand value.