China remains the world’s leading manufacturing hub for custom packaging, offering unmatched scale, technology, and cost advantages. However, to source packaging from China safely, buyers must follow a structured due diligence process. This guide explains how to reduce risk through effective packaging supplier verification and proven safe sourcing strategies.

Why Buyers Source Packaging from China

Global brands continue to rely on Chinese packaging manufacturers due to:

- Advanced printing and finishing capabilities

- Competitive production costs at scale

- Wide material selection and customization

- Mature export infrastructure

Reality Check: Cost advantages are real—but only when suppliers are properly vetted.

Step 1: Define Your Packaging Requirements Clearly

Before contacting suppliers, buyers should document:

- Exact box dimensions and structure

- Material specifications and certifications

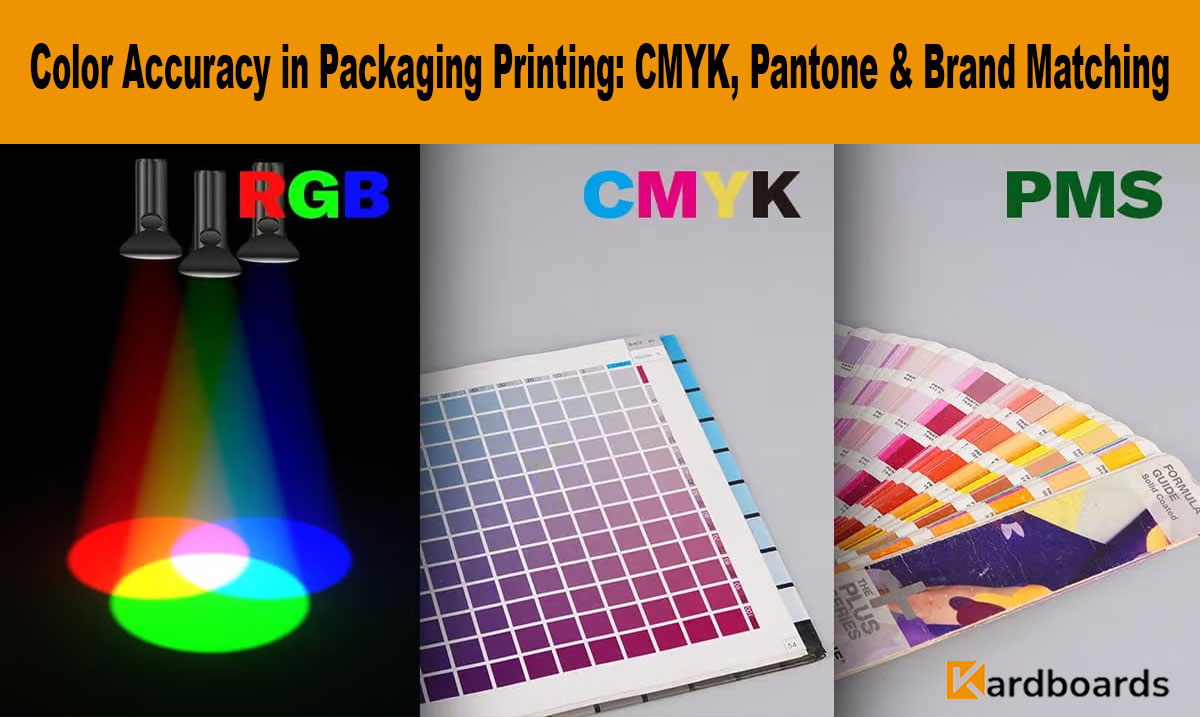

- Printing methods and finishing details

- Target order quantity and delivery timeline

Clear specifications prevent miscommunication and pricing surprises.

Step 2: Initial Supplier Screening

Effective packaging supplier verification begins with background checks.

- Company registration and export license

- Years of manufacturing experience

- Factory size, equipment, and workforce

- Packaging specialization and product focus

Tip: Avoid trading companies when you need direct factory control.

Step 3: Factory Audits & Certifications

Serious suppliers should provide evidence of compliance:

- ISO 9001 quality management certification

- FSC certification for sustainable packaging

- Sedex or BSCI social compliance reports

- Factory audit videos or third-party inspections

Step 4: Sampling & Prototyping

Never skip sampling when sourcing packaging from China.

- Pre-production samples validate materials

- Print proofs confirm color accuracy

- Structural samples test strength and fit

- Transit simulations identify weaknesses

Approved samples become the benchmark for mass production.

Step 5: Transparent Pricing & Contracts

Safe sourcing depends on clear commercial terms.

- Detailed cost breakdowns

- Clear MOQs and lead times

- Defined tooling and setup fees

- Written quality and tolerance standards

Risk Control: Always sign a purchase contract with quality clauses.

Step 6: Quality Control During Production

On-site or third-party inspections reduce risk:

- Pre-production material checks

- Mid-production quality inspections

- Final random inspections before shipment

- Packaging testing for durability and safety

Step 7: Logistics, Shipping & Documentation

Safe sourcing extends beyond manufacturing.

- Export packaging and palletization standards

- Accurate HS codes and customs documents

- Sea vs air freight optimization

- Insurance coverage for international shipments

Common Risks & How to Avoid Them

- Inconsistent quality: Use inspections and samples

- Hidden costs: Demand full quotations

- Delays: Confirm production schedules

- IP risks: Use NDAs and supplier agreements

How Kardboards Supports Safe Packaging Sourcing

Kardboards helps global buyers source packaging from China safely by offering:

- Verified factory partnerships

- End-to-end quality control

- Transparent pricing and documentation

- Export-ready logistics coordination

This structured approach minimizes risk while maximizing value.

Frequently Asked Questions

Is it safe to source packaging from China?

Yes, when suppliers are verified and quality controls are in place.

How do I verify a packaging supplier?

Check certifications, factory audits, samples, and export records.

Should I visit the factory in person?

Factory visits are ideal but third-party audits are a strong alternative.

What documents should a supplier provide?

Business licenses, certifications, inspection reports, and export documents.

How can I reduce sourcing risk?

Use clear specifications, contracts, inspections, and experienced partners.