Packaging Materials Compared: Paperboard, Corrugated, MDF & Rigid Boxes

Understand the strengths, limitations, and ideal applications of today’s most common packaging materials.

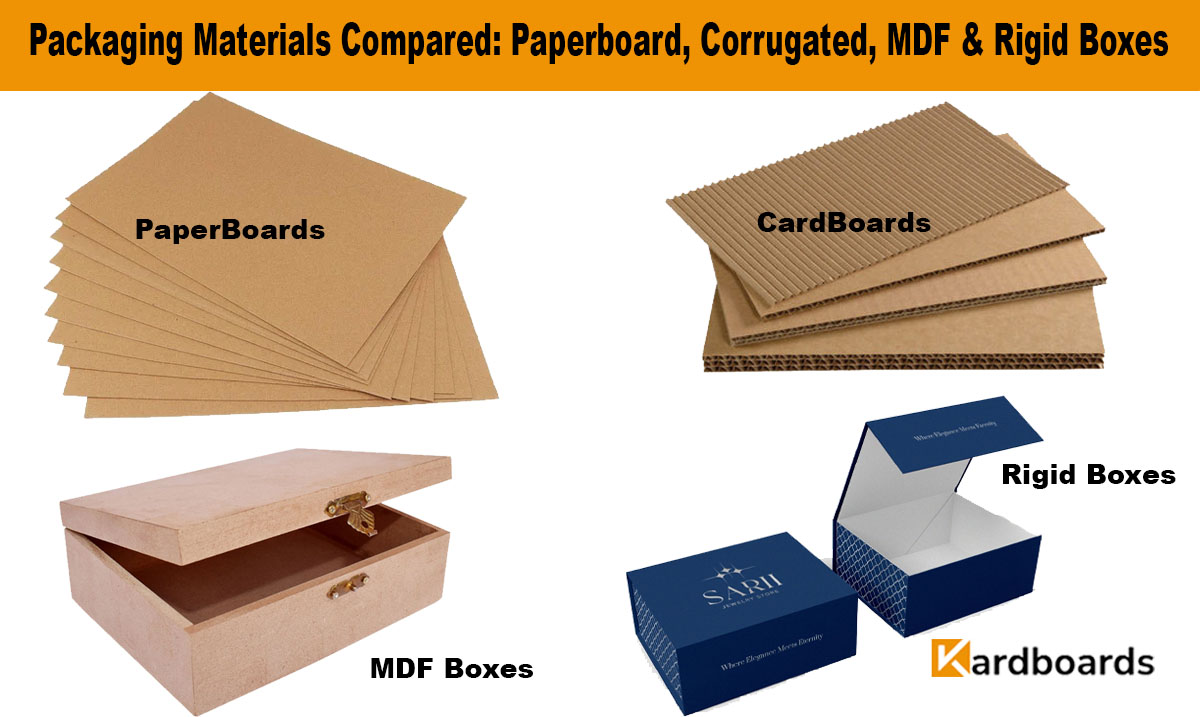

Choosing the right packaging material is one of the most important decisions for any brand. A clear packaging materials comparison helps businesses balance cost, protection, sustainability, and brand perception. In this guide, we compare paperboard, corrugated packaging, MDF boxes, and rigid boxes to help you select the best solution for your products.

Paperboard Packaging

Paperboard is a lightweight, flexible material commonly used for retail cartons and consumer packaging.

- Cost-effective and easy to customize

- Ideal for cosmetics, food, and pharmaceutical products

- Excellent print quality for branding

- Lower durability compared to rigid materials

Best For: High-volume retail products where branding matters more than heavy protection.

Corrugated Packaging

Corrugated packaging is made from fluted paper layers, offering superior strength and cushioning.

- Excellent protection during shipping

- Available in single, double, or triple wall options

- Cost-efficient for bulk transport

- Limited luxury appeal compared to rigid boxes

Corrugated boxes are widely used for e-commerce, logistics, and industrial applications.

MDF Boxes

MDF (Medium Density Fiberboard) boxes offer a balance between strength and premium aesthetics.

- Solid structure with smooth surfaces

- Suitable for luxury gift and presentation packaging

- Supports lacquer, veneer, and fabric finishes

- Heavier and less eco-friendly than paper-based options

Best For: Premium gifts, collectibles, and decorative packaging.

Rigid Boxes

Rigid boxes are manufactured from thick paperboard and are synonymous with luxury packaging.

- Exceptional durability and structure

- High-end unboxing experience

- Compatible with magnetic closures and inserts

- Higher cost and longer production time

Rigid boxes are commonly used for electronics, jewelry, luxury apparel, and high-value products.

Packaging Materials Comparison at a Glance

- Paperboard: Lightweight, affordable, highly printable

- Corrugated Packaging: Strong, protective, shipping-friendly

- MDF Boxes: Premium feel, solid construction

- Rigid Boxes: Luxury appearance, maximum brand impact

How to Choose the Right Packaging Material

Consider these factors when selecting packaging:

- Product weight and fragility

- Shipping and handling requirements

- Brand positioning and customer experience

- Sustainability and compliance needs

- Budget and production timelines

Why Material Choice Impacts Brand Value

Your packaging material directly influences how customers perceive your product. While corrugated packaging ensures safety, rigid boxes elevate perceived value. A thoughtful material choice strengthens brand trust and improves customer satisfaction.

Kardboards Packaging Material Expertise

Kardboards helps brands select the right materials based on product needs, market positioning, and scalability. From cost-efficient corrugated packaging to premium rigid and MDF boxes, we deliver solutions that align with your growth strategy.

Frequently Asked Questions

Which packaging material is best for e-commerce?

Corrugated packaging is ideal due to its strength, cushioning, and cost efficiency.

Are rigid boxes better than MDF boxes?

Rigid boxes are lighter and more commonly used for luxury retail, while MDF boxes offer a heavier, decorative feel.

Is paperboard packaging durable enough?

Paperboard works well for lightweight products but is not recommended for heavy or fragile items.

What is the most sustainable option?

Paperboard and corrugated packaging are generally the most recyclable and eco-friendly options.

Can different materials be combined?

Yes, many brands combine corrugated outers with rigid or paperboard inner packaging.