In global supply chains, packaging must withstand far more than simple handling. From warehouse stacking to cross-border transportation, packaging testing ensures products arrive intact. Understanding drop test packaging, compression testing, and transit packaging safety is essential for brands shipping domestically or internationally.

What Is Packaging Testing?

Packaging testing evaluates how packaging performs under real-world conditions such as impact, vibration, pressure, and environmental stress. These tests help manufacturers identify weaknesses before mass production and reduce costly product damage.

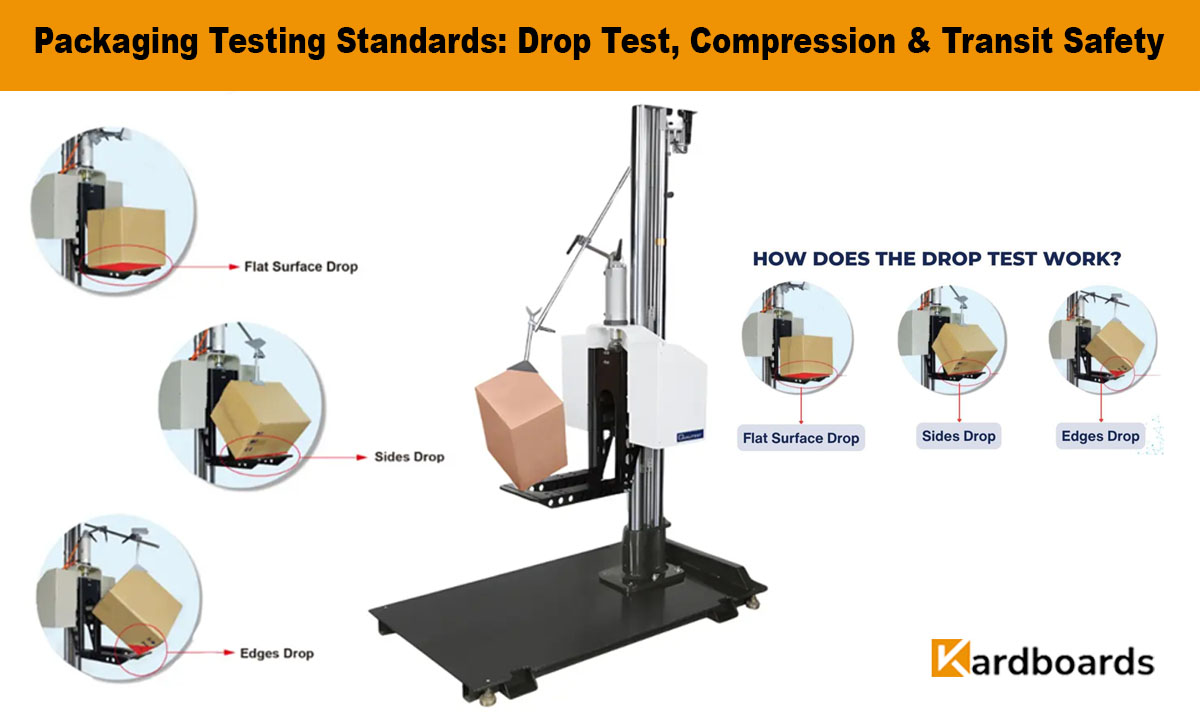

Drop Test Packaging Explained

The drop test simulates accidental drops during handling, loading, and last-mile delivery.

- Tests vertical, edge, and corner drops

- Replicates warehouse and courier handling

- Identifies cushioning and structural weaknesses

- Commonly required for e-commerce and retail packaging

Industry Insight: Even premium products fail if packaging is not optimized for repeated handling drops.

Compression Testing: Stack & Storage Safety

Compression testing measures how much weight a package can withstand before collapsing.

- Simulates pallet stacking in warehouses

- Prevents box deformation during long storage

- Critical for bulk shipments and export containers

- Helps optimize material thickness and flute selection

This test is especially important for corrugated and rigid packaging used in large-volume logistics.

Transit Packaging Safety & Vibration Testing

During transportation, packages are exposed to constant vibration from trucks, ships, and air cargo. Transit packaging safety testing replicates these conditions.

- Simulates long-distance shipping vibrations

- Tests internal product movement and abrasion

- Validates inserts, dividers, and cushioning materials

- Reduces internal damage without overpacking

Common Packaging Testing Standards

Professional manufacturers follow internationally recognized testing protocols:

- ISTA standards for distribution simulation

- ASTM testing for compression and impact

- ISO guidelines for quality consistency

- Custom tests based on client logistics routes

Why Packaging Testing Matters for Global Brands

- Reduces product damage and returns

- Protects brand reputation and customer satisfaction

- Optimizes material usage and cost efficiency

- Ensures compliance with retailer and marketplace requirements

Smart Packaging: Well-tested packaging often uses less material while offering better protection.

Packaging Testing at Kardboards

Kardboards integrates packaging testing into every development phase:

- Drop test packaging validation for e-commerce and retail

- Compression testing for export and bulk shipments

- Transit simulation for international logistics

- Data-driven refinement before mass production

This approach ensures every box meets performance expectations across global supply chains.

Frequently Asked Questions

What is the purpose of packaging testing?

Packaging testing ensures products remain protected during handling, storage, and transportation.

How high are drop tests typically performed?

Drop heights vary based on product weight and shipping method, often between 30–100 cm.

Is compression testing necessary for small products?

Yes, especially when products are stacked in warehouses or shipped in bulk cartons.

Does packaging testing increase costs?

Testing reduces long-term costs by minimizing damage, returns, and overpackaging.

Can custom packaging be optimized after testing?

Absolutely. Testing results are used to refine materials, structure, and cushioning.